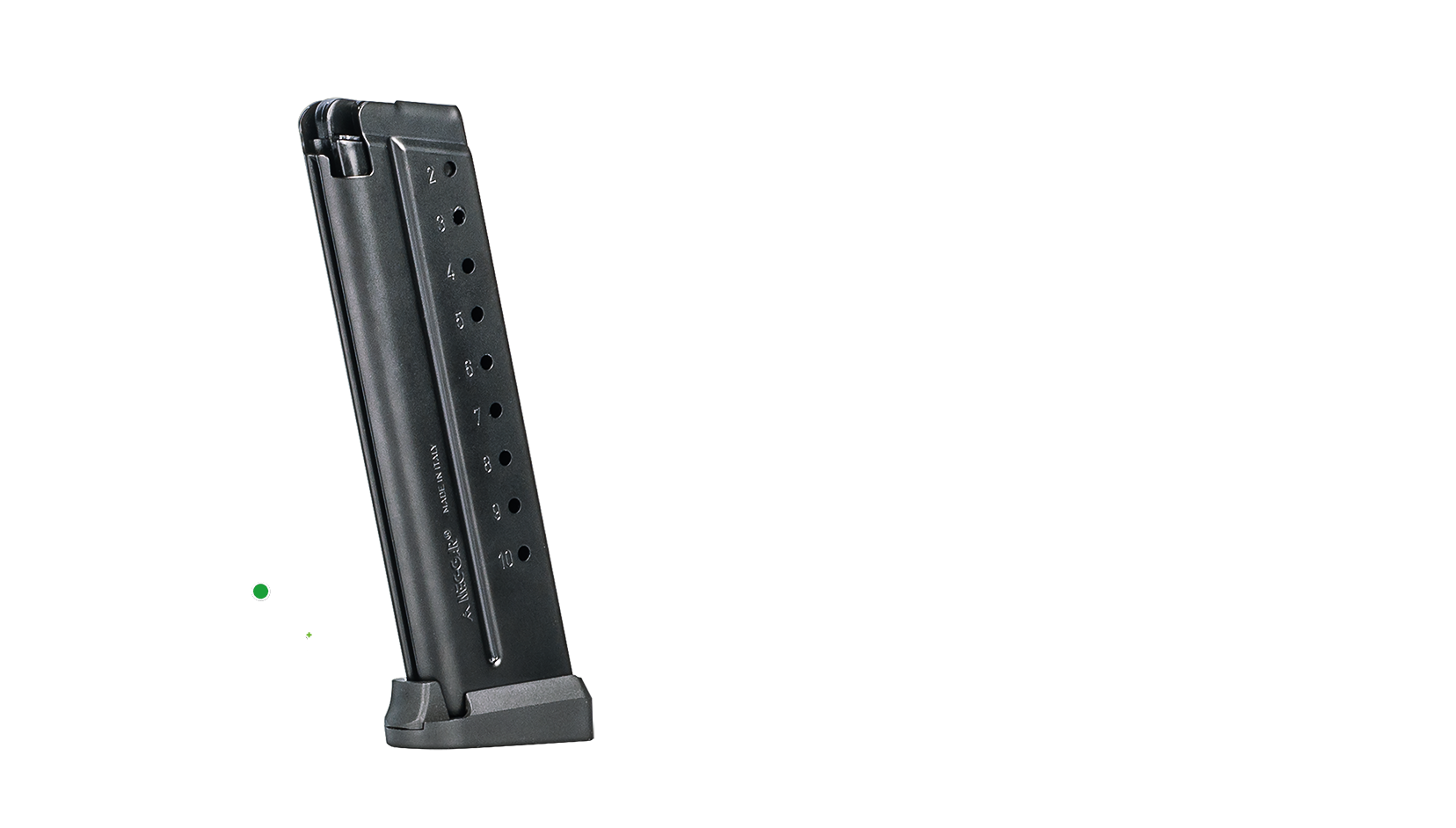

Mec-Gar, the most trusted magazine manufacturer in the world with over 250 different models and 130 million OEM magazines, engineered and supplied to customers worldwide.

Mec-Gar

The World's Finest Magazines

The worldwide leader in firearm magazines manufacturing for both OEM and aftermarket customers.

Our quality is unmatched by anyone else in the industry.

+60 Years of Unmatched Performance

Since 1965 Mec-Gar distinct advantage is as a “one-stop-shopping-center” for technical design assistance, prototypes, tool design and development, metal stamping and assembly.

Mec-Gar offers innovative, reliable and efficient solutions. Our manufacturing operations are housed in three modern facilities with more than 82,000 sq ft located in Gussago, in the Italian province of Brescia.

Mec-Gar, always on the forefront of magazine design.

Magazines Sold

Manufacturing Space

Employees

Years In The Making

The World's Finest Magazines

Welcome

to the digital industry 4.0

State-of-the-art Manufacturing

With over 75,000 sq ft of manufacturing space across three modern facilities, Mec-Gar maintains a fully equipped metal stamping department including automatic presses, automatic seam-welding machines, and cutting edge robotic technology to assist in the stamping and welding process resulting in improved quality, tolerances, and output.

Mec-Gar magazines feature perfectly interchangeable components which are the result of the finest precision stamping, bending and drawing operations.

Our in-house heat treatment system monitors the entire process from the hardening step to the stress relief; all variables are kept under control so our parts comply to the tightest specifications.

Thousands of components are needed when manufacturing hundreds of different models of magazines: our skilled assembly department catalogs parts and assembles thousands of magazines daily.

With a professional in-house state of the art tool and die facility with experienced designers and toolmakers, we can offer product engineering support along with diversified prototype development.

Integrated CAD-CAM technology is employed at Mec-Gar in order to fabricate high precision compound and progressive dies, tools and gauges designed to meet the most stringent tolerance specifications.

Using the best materials is of paramount importance that is why we take into account tensile strength, elongation rate and chemical composition of all raw materials. Before materials are accepted into production they are carefully tested and checked. Our magazines are made from certified AISI 1010 Carbon Steel or from superior aircraft-grade 17-7 PH stainless steel.

Mec-Gar Quality Management System

Considering the stringent testing guidelines and exacting requirements of military and law enforcement customers around the world, our magazines meet or exceeded their compliance and tolerance guidelines. We live by a policy mandating quality by being committed to the manufacturing of consistently superior quality magazines compared to our competitors.

At Mec-Gar we focus on putting customers first. By becoming IS0 9001:2015 compliant, we demonstrate our ability to effectively and efficiently provide a quality management system while continuously improving their internal process which helps ensure that customers receive consistent, high quality products and services.

Download Mec-Gar ISO 9001:2015 Certificate - PDFAll manufacturing is performed in-house, resulting in improved quality, tolerances, and output.

In-house engineers and toolmakers offer assistance from design consultation through final manufacturing.

Since 1965 we do innovation.

Proud to present our R&D department